Rubber vulcanizing Tester solution|types of rubber testing : department Store ASTM D624 is a common test method used to determine the tear strength of vulcanized rubber and thermoplastic elastomers. Due to the specimen shapes often used, this test is sometimes called a trouser, angle, or crescent test. 1,192 likes, 19 comments - shoppingdailha on August 17, 2023: "O Circo Americano chega ao Shopping da Ilha para animar o seu dia e proporcionar mais uma opção."

{plog:ftitle_list}

Resultado da Vestido Paris. A Ghetti Store sempre foi um sonho que começou a se tornar realidade neste ano de 2022 de forma online. Aqui buscamos atender todo .

Proper tensile testing of vulcanized (durable) rubber and thermoplastic elastomers per ASTM D412 is quite useful since these compounds are one of the most complex and universally used .An advanced and fully automated rubber testing solution for high capacity manufacturers of rubber compounds. Download Brochure Request Quote.ASTM D624 is a common test method used to determine the tear strength of vulcanized rubber and thermoplastic elastomers. Due to the specimen shapes often used, this test is sometimes called a trouser, angle, or crescent test.

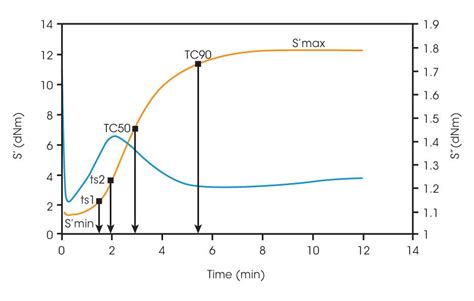

Oscillation tests are popular for studies of curing, or vulcanization, as well as measurements of viscoelastic properties, filler structure, polymer architecture, and more for both green and cured rubber.Rubber test mixes — Preparation, mixing and vulcanization — Equipment and procedures 1 Scope This International Standard specifies the equipment and procedures for the preparation, .Introducing the NG-MDR Moving Die Rheometer, your solution for accurately assessing the curing and processing characteristics of vulcanized rubber compounds. Designed for precision, this state-of-the-art rheometer captures .

The Tensile/Elongation (D412) test methods cover procedures used to evaluate the tensile (tension) properties of vulcanized thermoset rubbers and thermoplastic elastomers.This International Standard specifies the equipment and procedures for the preparation, mixing, and vulcanization of rubber test mixes specified in the various International Standards for the .

In this chapter we will direct out attention to the test procedures and instruments used to measure two of the most critical properties of rubber and rubber compounds, processibility and .We provide a detailed explanation of the Rubber Vulcanization Process, including the role of the vulcanizing agent, temperature control, and reaction mechanisms.Vulcanization, chemical process by which the physical properties of natural or synthetic rubber are improved; finished rubber has higher tensile strength and resistance to swelling and abrasion, and is elastic over a greater range of .

types of rubber testing

Rubber, vulcanized or thermoplastic — Determination of indentation hardness. AHT: NF T46-052: Rubber, vulcanized or thermoplastic – Determination of indentation hardness – Part 1: durometer method (Shore hardness). AHT: . 5.1 This test method is used to determine the vulcanization characteristics of (vulcanizable) rubber compounds. 5.2 This test method may be used for quality control in rubber manufacturing processes, for research and development testing of raw-rubber compounded in an evaluation formulation, and for evaluating various raw materials used in Test Type: Low Temperature Impact Recommended Model DCL-5003 rubber and plastic low temperature brittleness testing machine. According to GB / T1682-94 "vulcanized rubber low-temperature brittleness test the single sample test" national standard design, the latest research and development of the compressor refrigeration equipment.Vulcanizing Chamber: The central unit where the rubber undergoes the vulcanization process.It is designed to withstand high temperatures and pressures. Control System: Ensures precise regulation of the vulcanization conditions, including temperature, pressure, and time.This system is crucial for achieving the desired physical and chemical properties of the rubber.

How to Perform a Tear Strength Test on Vulcanized Rubbers and Thermoplastic Elastomers. Written by Kayla Thackeray . ASTM D624 is a common test method used to determine the tear strength of vulcanized rubber and thermoplastic elastomers. Due to the specimen shapes often used, this test is sometimes called a trouser, angle, or crescent test .Rubber Cement and Vulcanizing Fluids for Patching Tire Tubes . At some point in time, there may be a need to remedy a small leak or a burst to your tire tubes. Therefore, adhesives made up of rubber cement or vulcanizing fluids are common products used to patch tire tubes and make them useful again. . The Best Solution is a Patch Kit. The .

By Ann Marie Somma. Charles Goodyear’s discovery of the vulcanization of rubber—a process that allows rubber to withstand heat and cold—revolutionized the rubber industry in the mid-1800s.Automotive tires, pencil erasers, life jackets, balls, gloves, and more are all in commercial use because of Goodyear’s relentless experimentation to unlock the .

vulcanized rubber immediately after de-molding when the freshly formed rubber-to-metal bond is still at a relatively high temperature. These problems are typically encountered in the manufacture of concentric bush components in which the rubber is bonded between an outer and an inner concentric metal tube.ASTM D429 test standard determines the adhesion of rubber to rigid metal substrates. This test standard is divided into methods A through H. Common application examples that use tests in ASTM D429 are vehicle engine mounts, vehicle suspension bushings, rubber-coated metal parts, and rubber-lined tanks and containers. Most of the tests involve orthogonal tensile strength or .Paracure ZOI-52: General all-purpose zinc oxide dispersion suitable for most vulcanization applications. Paracure 811: Unique total curing package designed for curing and vulcanizing of various foam latex polymer recipes. Paracure 850: High quality sulfur dispersion with accelerator. Paracure DPG: Sulfur Vulcanization Cure package additive.

Blends of natural rubber and styrene-butadiene rubber were prepared by solution mixing and vulcanized with a system sulfur–accelerator at 433 K and 443 K in order to study the vulcanization kinetic and the influence of the vulcanization temperature on the final structure of the blends.The kinetic of vulcanization was analyzed under the frame of the Han’s model, .According to the safety sheet of the vulcanizing solution type D intended for tyre repair made by Ferdus it is "solution of a rubber compound in liquid hydrocarbons predominantly of a paraffinic character", i.e. C6-C7, n-alkanes, isoalkanes, cyclic, <5% n-hexane) 92%, in which there is: cyclohexane 10%, n-hexane < 5%. An old version of the .

Vulcanized rubber is tougher and less likely to decompose than natural rubber, but there is evidence that vulcanized rubber will biodegrade in hot composting bins. The benefit of vulcanization is that rubber products can easily be refurbished or . Oliver Rubber Industries LLP specializes in cold vulcanizing solutions for conveyor belt maintenance. Their flagship product, OM 2000 Cement, boasts a 'BOND .

rubber oscillation test

The Plate vulcanizing press is a kind of equipment used in the production of rubber products, mainly used for the vulcanization of rubber products. Vulcanization is a key step in rubber processing. Trusted Worldwide Supplier of Quality Equipments and Materials For Your Lab!The test sample extracted with benzene is placed under nitro-gen and then treated with a 0.2 M solution of propane-2-thiol dissolved in 0.4 M . 6 days to break only the polysulfidic a bc ed Sx S2 S A Sy f ed SS S x>3__ y>1 Fig. 5.3 Typical chemical bonds formed in sulphur vulcanized rubber: (a) polysulfid cross-links, (b) disulfid cross linksTag: vulcanizing rubber solution. Home / Products tagged “vulcanizing rubber solution .It is critical to understand that the cold vulcanizing solution must meet a few parameters in order to bind the HR/FR conveyor belts. Oliver Rubber's GB-3150 is the finest cold-vulcanizing cement for such belts. OUR YOUTUBE VIDEO . Frequently Asked Questions (FAQs) Q1: Why choose a cold vulcanizing kit for conveyor belt repairs?

2. Adhesive System- The second choice is the adhesive system. The adhesive system must provide an excellent bond under the specified vulcanization conditions, as well as maintain its bond under service conditions. Elastomers. Natural rubber and many synthetic elastomers make up the range of rubber polymers that are available for fabrication. Natural rubber (NR) and styrene butadiene rubber (SBR) rubber blends solution were blend at 7 different ratios of 100/0, 80/20, 70/30, 60/40, 50/50, 40/60 and 0/100 and were dissolved in toluene. Vulcanization of rubber uses heat and sulfur (or another chemical) to form a hardened cross-linked polymer. Vulcanization or vulcanisation (British) is a process of hardening rubber using chemicals and (usually) heat. Originally, vulcanization described the treatment of natural latex rubber with heat and sulfur.While this remains the most common type of .

Tire Repair Chemicals, Cements, vulcanizing, vulcanizing cements, pre buff rubber cleaner, rubber cleaner, solvents, pre buff cleaner aerosol, blue float gum, a b compound, A + B Compund, buffing solutions, brake and parts cleaner, degreaser, liquid patch, tire talc, safety seal, Ascot, Rema . 5578 Thermopress MTR Solution 1kg. Can âš . The mixture was stored at room temperature for 12 h, followed by vulcanization at an optimum cure time (Tc90) and a temperature of (160 °C) with a flat vulcanizing machine (Qianpu XLB-D; Ningbo, China). The Tc90 was obtained with a rubber vulcanization tester (GOTECH M-3000; Taiwan, China). 2.4. CharacterizationsLab Flat Press Vulcanizing Machine for Vulcanizing Rubber Solution Laboratory small flat vulcanizing machine is also called hot press forming machine. It is mainly used for sample preparation of vulcanised rubber and plastic products, such as: tensile test, impact test, compression test, etc. Blends of natural rubber (NR) and styrene-butadiene rubber (SBR) were prepared by solution mixing and vulcanized with sulfur and accelerator in a Semi-EV system at 433 K and 443 K in order to study the vulcanization kinetic and the influence of vulcanization temperature on final structure of the blends.

Rubber vulcanization is a process consisting of a mixture of rubber and a curing ingredient, often sulfur, which is then heated under pressure. This process makes the rubber more elastic, more durable, and more resistant to extremes in temperature. For Lab Italia is an ISO 9001:2015 certified company that produces ovens “made in Italy” for curing and “post curing” rubber .

liquid drop test amazon fullfillment

liquid drop test kits for flouride

Resultado da Euro Truck Simulator 2 İndir – Tek Link 84 DLC 1.49.2.6s. Nis 17, 2023 4506. Euro Truck Simulator 2, 19 Ekim 2012’de SCS Software firması tarafında yayınlanmış bir kamyon oyunudur. Scania, Volvo, MAN, DAF, Iveco, Renault gibi markaların lisanslı.. Devamını Oku.

Rubber vulcanizing Tester solution|types of rubber testing